-40%

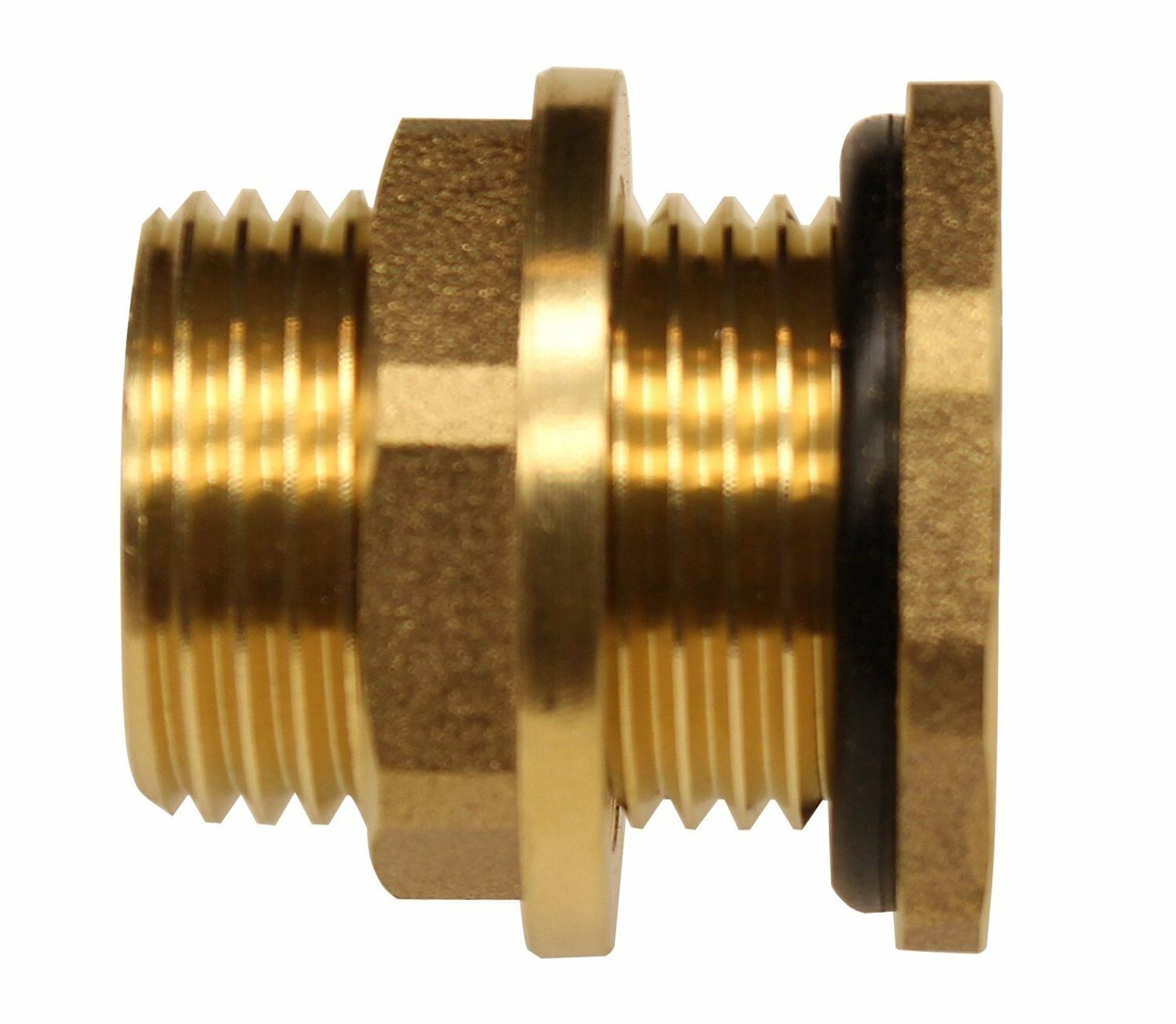

3/4" Stainless Steel Bulkhead Fitting - Tank Adapter - Storage Tank Bulkhead

$ 28.48

- Description

- Size Guide

Description

3/4" Stainless Steel Bulkhead Fitting- Perfect for the self-sufficient homesteader, rancher, or farmer, this tank bulkhead fitting is crafted of high quality 316 Stainless Steel, and is ideal for use on anything from your 55-gallon blue barrel to your 10,000 gallon storage tank! Being made of Stainless Steel makes it ideally suited for a wide variety of applications, including agriculture, reverse osmosis systems, indoor farming, rainwater harvesting, well water storage and purification systems, and many more! Here are a few of the features you will love:

100% 316 Stainless Steel Construction

– store potable water, DEF, liquid feed, fertilizer, and much more!

Industry Standard NPT Threaded all the Way Through

– easily attach plumbing inside the tank, like a siphon tube, and outside the tank, like a ball valve

Easy to Install

– just drill a 1 5/16” hole, feed the barrel through from the inside, and tighten the nut!

EPDM Gasket

– safe for use in your drinking water storage tank

Heat Resistant

- both the gasket and fitting itself perform well at high temperatures

Versatile

- install it on drums, barrels, and tanks with a wall thickness up to 5/8"

However, what really sets this tank adapter apart from the rest is its “wrenchability”. If you are a seasoned installer out of the field, then you know that nothing is more frustrating than attempting to install a bulkhead that keeps moving on you. Enter the Pipe Fitting Store bulkhead, manufactured with grooves designed specifically for a 1 1/8” wrench to grab the barrel of the fitting while you tighten the nut and complete your tank tap. It is what makes this bulkhead an installers dream!

Common Compatible Liquids (not an exhaustive list)*:

Potable and Non-Potable Water

Diesel Exhaust Fluid (DEF)

Ethanol/Ethyl Alcohol

Most Fertilizers

Ammonium Nitrate

Most Detergents and Soaps

Hydrogen Peroxide (less than 10% concentration)

Liquid Feed

Liquid Sugar and Molasses

Synthetic Hydraulic Oil (non-petroleum based)

Citric Aced

Sodium Peroxide

Diethylene Glycol

Vinegar

Methanol/Methyl Alcohol

Potassium Sulfate

Ammonium Acetate

Ketones

Let us know if you have any questions – we are happy to help. At Pipe Fitting Store, we know your business is earned, not merely given. And, as part of our commitment to earning your business, all orders ship within one business day!

*

The information in this chart has been supplied to Pipe Fitting Store by other reputable sources and is to be used ONLY as a guide in selecting equipment for appropriate chemical compatibility. Before permanent installation, test the equipment with the chemicals and under the specific conditions of your application, and consult the chemical manufacturer to ensure compatibility.

Pipe Fitting Store does not warrant (neither express nor implied) that the information in this chart is accurate or complete or that any material is suitable for any purpose.

Variations in chemical behavior during handling due to factors such as temperature, pressure, and concentrations can cause equipment to fail, even though it passed an initial test.

Use suitable guards and/or personal protections when handling chemicals.